ASME U v NBIC R Stamps: Key Differences in Pressure Vessel Fabrication

If you are responsible for pressure vessels in your plant, you have likely heard about ASME U and National Board R stamps. Both certifications are...

5 min read

%20(1).png) Burkes

:

Updated on January 26, 2026

Burkes

:

Updated on January 26, 2026

Table of Contents

Selecting the right coating for corrosive environments means choosing a system tailored to your specific exposure, substrate material and service-life objective so corrosion is avoided rather than just managed. In this blog post we’ll walk you through how to match your environment, substrate and durability goals to the correct coating system and inspection practices so your asset delivers reliable performance.

Coatings for corrosive environments are engineered paint systems that shield steel and concrete from chemical attack, moisture, temperature cycling, abrasion, and UV. The most reliable protection comes from a system approach that pairs correct surface preparation with the right primer, build coats, and topcoat.

In heavy industry, the environment dictates how fast unprotected steel would corrode. ISO 12944 provides the common language for that environment by classifying corrosivity from C1 to CX and aligning it with tested coating systems and durability ranges. When you match your coating stack to the real exposure, you control lifecycle cost and avoid preventable downtime.

Corrosivity categories determine the minimum film build and whether you need galvanic protection from zinc. In C4 to CX atmospheres, zinc-rich primers with high-build epoxies and UV-resistant topcoats are commonly specified to reach medium to high durability targets.

ISO 12944:2018 consolidated the severe classes and added CX for extreme offshore and industrial exposures. That change clarified when specifiers should move from a traditional epoxy-polyurethane stack to higher performance systems for aggressive salt and humidity.

Three factors dominate: immersion versus atmospheric exposure, chemical type and concentration, and operating temperature. Immersion and splash zones often require immersion-grade epoxies, novolac epoxies, or vinyl esters, while atmospheric exposures frequently use zinc primer, epoxy intermediate, and polyurethane topcoat for long UV life.

Service temperature shifts the chemistry. Many ambient-cure epoxies lose performance near their glass transition temperature, while novolac epoxies, phenolics, or heat-cured epoxies extend resistance for hot, acidic, or solvent splash. Always confirm against product data aligned with ISO 12944 system guidance.

Anchor specifications to ISO 12944 for environment and durability, and to AMPP/SSPC standards for surface preparation quality. When the environment and prep match the tested system, service life becomes predictable.

ISO 12944 supplies the framework for corrosivity, durability classes, and typical paint systems. AMPP surface preparation standards such as NACE No. 2/SSPC-SP 10 define how clean the substrate must be for adhesion and long-term performance. Together they form a common specification language across owners, inspectors, and applicators.

ISO 12944 maps environmental categories to expected durability ranges and representative coating systems. It also distinguishes atmospheric service from immersion categories to prevent mis-specifying an atmospheric stack for a tank interior or splash zone.

For example, as you move from C3 to C5 and into CX, recommended systems add film build, zinc galvanic protection, and more chemically robust intermediates. Selecting by category and target service life lets you balance capital cost with maintenance intervals.

Specify the blast grade that the coating manufacturer and durability goal require. Near-white metal, NACE No. 2/SSPC-SP 10, is a common choice for critical steel because it allows only minimal staining and drives reliable adhesion.

Other grades include SP 5 white metal for the cleanest substrate and SP 6 commercial blast where risk is lower. These standards spell out cleanliness and how to verify it, including profile, contamination limits, and environmental controls.

NACE Level 2, now AMPP CIP Level 2, is an advanced coatings inspection qualification. Bringing a Level 2 inspector onto your project adds documented quality checks, calibrated instrumentation, and proactive issue detection that reduces rework.

The Level 2 curriculum covers non-destructive and destructive testing, environmental monitoring, specialty linings, and inspection planning across steel and non-steel substrates. That breadth helps align field work with specification and manufacturer limits so your system reaches its intended life.

Inspectors confirm surface prep grade, ambient conditions, salt contamination limits, profile, dry film thickness, holiday detection, and cure status before service. They also manage hold points and records that close the loop between design and execution.

AMPP’s course description highlights documentation discipline and instrumentation use, both essential for traceable QA/QC. This verification is the difference between a coating that looks good on day one and one that performs year after year.

Use a system approach built around exposure: galvanic protection from zinc where undercutting risk is high, barrier protection from high-build epoxies, and UV stability from polyurethane or polysiloxane topcoats. In immersion, upgrade to immersion-grade epoxies or vinyl esters.

Polysiloxanes can reduce coat count while offering excellent gloss and color retention due to their silicon-oxygen backbone. Where sunlight, salt spray, and abrasion meet, they are a proven topcoat option.

Zinc-rich primers: High salinity or industrial atmospheres from C4 through CX to resist undercutting and provide sacrificial protection.

High-build epoxies: Barrier protection for atmospheric or splash zones and broad chemical resistance.

Novolac epoxies: Strong acids and solvents, higher temperature splash and immersion service.

Vinyl esters: Aggressive chemicals and immersion where fast return to service or higher temperature tolerance is needed.

Polyurethane or polysiloxane topcoats: UV durability, color and gloss retention in outdoor service.

Select combinations using ISO 12944 tables and manufacturer data validated for your chemicals and temperature.

As operating temperature rises or pH drops, upgrade resin chemistry. Novolac epoxies and phenolic systems hold film integrity and chemical resistance where standard epoxies soften. If UV and aesthetics matter, pair the high-build layer with a polyurethane or polysiloxane topcoat rated for the heat load.

For units that cycle between ambient and hot splash, confirm continuous and intermittent temperature limits for each layer. The wrong assumption here shortens service life more than any other single selection error.

Treat CUI as its own threat profile. NACE SP0198 recommends immersion-grade coatings under insulation, sound water management, and details that allow drainage and inspection. Selecting the correct coating without fixing water ingress rarely solves CUI.

Industry literature reinforces that system design, not just coating choice, controls CUI risk. Plan for inspection ports, avoid moisture traps, and design terminations that shed water. When insulation stays dry and the substrate has the right coating, CUI rates drop sharply.

Apply immersion-grade coatings on insulated steel, select insulation that limits water retention, and design for drainage, venting, and access. Maintain seal integrity at penetrations and terminations where most leaks start.

SP0198 is the accepted practice for CUI mitigation across refining, petrochemical, and power markets. Using its guidance in the design phase is far cheaper than repairing deep wall loss during an outage.

Follow a consistent workflow tied to standards and real site data. When owners, inspectors, and applicators use the same steps, results become repeatable.

Steps:

Classify the environment using ISO 12944 corrosivity category and target durability.

Define exposure by zone as atmospheric, splash, immersion, or CUI. Align each zone with a tested system.

Set surface preparation to the required standard. For critical steel, NACE No. 2/SSPC-SP 10 is common. Verify profile and salts.

Select chemistries that match chemicals and temperature, upgrading to novolac or vinyl ester for hot, aggressive service.

Specify inspection by NACE Level 2 to validate ambient conditions, DFT, holidays, and cure before service.

Document QA/QC with hold points and records that support warranty and future maintenance.

Collect operating temperature ranges, chemicals and concentrations, cleaning practices, desired service life, and whether insulation or fireproofing is present. Add substrate condition, expected abrasion, and UV exposure so the system can be tailored to each zone.

These inputs map directly to ISO 12944 durability classes, CUI strategies in SP0198, and the correct surface preparation grade. Clear data up front prevents change orders and short coating life later.

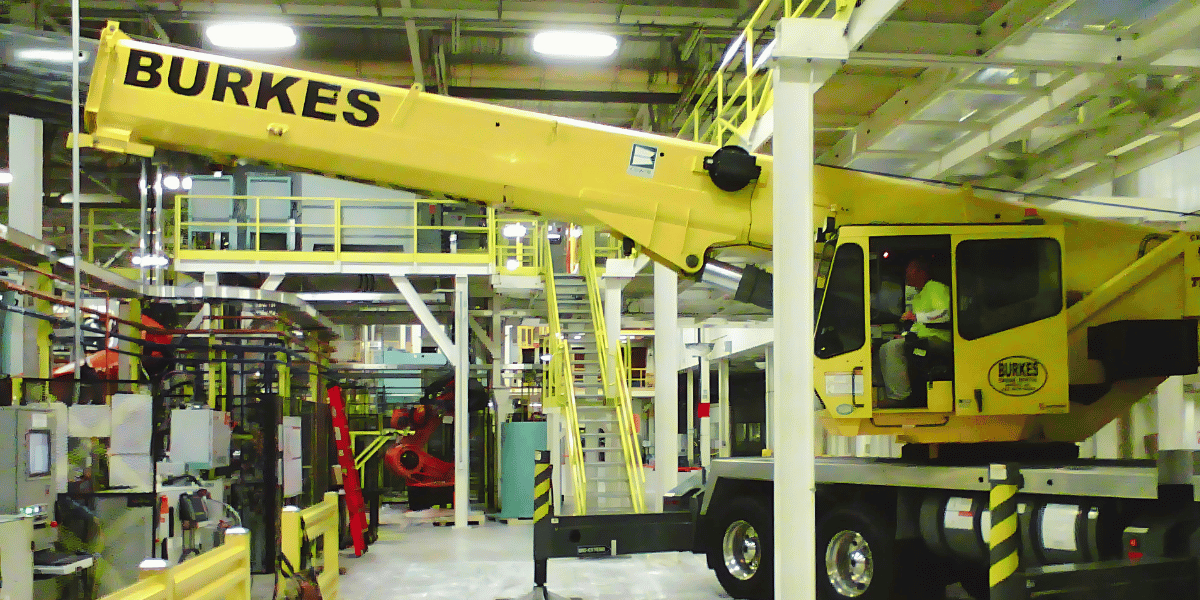

Burkes Mechanical pairs AMPP standards with practical field experience. Our teams classify environments per ISO 12944, prepare steel to the specified AMPP/SSPC grade, and apply proven coating stacks to hit your service life target.

We integrate NACE Level 2 inspection into the plan of work, not as an afterthought. That means consistent ambient control, calibrated gauges, traceable film-build checks, and defect repair before service, documented from surface prep through final cure.

Certified inspectors catch issues while fixes are fast, whether that is salt contamination after blasting, out-of-range humidity, or under-thickness on edges and welds. The result is lower rework, fewer leaks, and coatings that meet warranty terms.

With Burkes Mechanical you get one accountable team for specification review, surface prep, application, and inspection. That single-point responsibility shortens schedules and protects uptime on shutdown-critical work.

%20(1).png)

If you are responsible for pressure vessels in your plant, you have likely heard about ASME U and National Board R stamps. Both certifications are...

When it comes to industrial construction and maintenance, choosing between a national contractor and a trusted local partner can make or break a...

Modular construction reduces plant downtime by shifting the majority of fabrication and assembly offsite, allowing facilities to maintain operations...