What’s the Difference Between ASME U, S, and NBIC R Stamps?

When you manage a plant or capital project, you live with the constant pressure of compliance, uptime, and safety. Boilers, tanks, and pressure...

3 min read

%20(1).png) Burkes

:

Updated on March 4, 2026

Burkes

:

Updated on March 4, 2026

Table of Contents

If you are responsible for pressure vessels in your plant, you have likely heard about ASME U and National Board R stamps. Both certifications are vital for safe and compliant operations, but they apply to very different situations. Knowing the difference helps plant managers, project engineers, and procurement leaders avoid downtime, inspection failures, and costly rework.

Here is a Q&A guide that answers the most common questions about U and R stamps.

The U stamp is issued by the American Society of Mechanical Engineers (ASME). It authorizes a fabricator to build new pressure vessels in compliance with Section VIII of the ASME Boiler and Pressure Vessel Code.

To meet U stamp requirements, the fabricator must:

Bottom line: The U stamp verifies that a new vessel is inspection-ready, legally recognized, and safe for long-term operation.

The R stamp is issued by the National Board of Boiler and Pressure Vessel Inspectors. It authorizes a contractor to perform repairs and alterations on existing pressure vessels or boilers that were originally built under ASME code.

R stamp work can include:

Bottom line: The R stamp ensures that pressure vessel repairs or alterations restore the equipment to full code compliance.

The difference comes down to new construction versus repair or alteration:

Both require Authorized Inspector involvement, complete documentation, and strict adherence to code. The U stamp covers fabrication of new assets, while the R stamp keeps existing equipment legally operable after repairs.

Choosing the right stamp is not optional—it affects compliance, safety, and cost control.

In short, the wrong choice can mean downtime, liability issues, and wasted capital.

Here is a simple decision framework:

As a rule of thumb: new construction requires a U stamp, while repairs or alterations require an R stamp.

Yes. Here are practical situations:

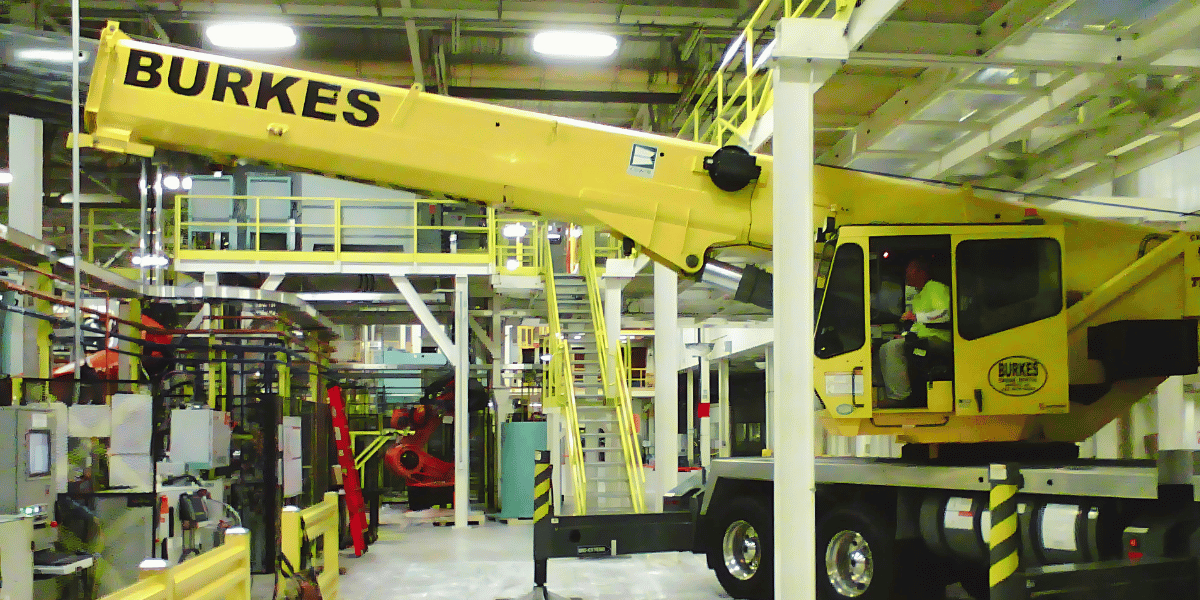

Burkes Mechanical holds both U and R certifications and provides:

With an EMR of 0.47 and zero OSHA citations in the past three years, Burkes is the reliable choice for high-stakes pressure vessel projects across the Southeast.

If you hire a contractor who is not U or R stamp certified, the risks include:

Choosing a certified partner the first time is always the safer and more cost-effective decision.

If your project involves new vessel fabrication, you need a U stamp. If it involves repairs or alterations on an existing vessel, you need an R stamp. Both require oversight by an Authorized Inspector and full compliance with ASME and NBIC standards.

When your project demands the highest level of safety and compliance, Burkes Mechanical is equipped to deliver both U and R stamp services with complete documentation and proven safety performance.

When you manage a plant or capital project, you live with the constant pressure of compliance, uptime, and safety. Boilers, tanks, and pressure...

1 min read

Burkes Mechanical outperforms national contractors by combining deep Southeast expertise, rapid mobilization from our Alabama and Florida bases,...

Modular construction reduces plant downtime by shifting the majority of fabrication and assembly offsite, allowing facilities to maintain operations...