ASME U v NBIC R Stamps: Key Differences in Pressure Vessel Fabrication

If you are responsible for pressure vessels in your plant, you have likely heard about ASME U and National Board R stamps. Both certifications are...

3 min read

%20(1).png) Burkes

:

Updated on January 26, 2026

Burkes

:

Updated on January 26, 2026

When you manage a plant or capital project, you live with the constant pressure of compliance, uptime, and safety. Boilers, tanks, and pressure vessels are the backbone of industrial operations, but they also carry significant risk. That is where ASME and National Board of Boiler and Pressure Vessel certifications come in. These stamps, U, R, and S, are not just symbols on a nameplate. They are documented proof that your equipment was designed, fabricated, or repaired according to the strictest codes in the industry.

The challenge is that not every contractor has the qualifications to perform stamped work. If you do not know the difference between U, R, and S stamps, it is easy to choose the wrong partner and end up with delays, compliance violations, or costly rework. Let’s break down what each stamp means, why they matter, and how Burkes Mechanical helps you meet code requirements without sacrificing schedule or budget.

The U stamp applies to new pressure vessels fabricated under ASME Boiler and Pressure Vessel Code Section VIII, Division 1 from 15 psi up to 3000 psi.

Key requirements include:

Why it matters: For industries such as chemical, pulp and paper, and petroleum, new vessels are capital assets expected to operate safely for decades. A U stamp provides regulators, insurance carriers, and facility owners with confidence that the vessel is inspection-ready from day one.

The S stamp certifies work performed under Section I of the ASME Boiler and Pressure Vessel Code. While some contractors fabricate complete boilers, Burkes Mechanical focuses on external boiler piping work. This includes piping from the boiler out to the second valve, as well as boiler feedwater and steam piping connections.

Key requirements include:

Why it matters: Boiler systems operate under extreme conditions, and any weak point in the piping or connections can create major safety risks. The S stamp proves that Burkes’ boiler-related piping fabrication and installation follow the highest standards of safety and compliance.

Over time, every vessel or boiler will need a repair, whether due to corrosion, fatigue, or an operational incident. The R stamp, issued by the National Board of Boiler and Pressure Vessel Inspectors, certifies that a contractor is authorized to perform repairs or alterations in compliance with NBIC standards.

Typical applications include:

Why it matters: Without an R stamp, repairs may not be legally recognized. That can result in failed inspections, higher insurance premiums, or even unplanned shutdowns. For plant managers, the R stamp ensures your equipment can return to service quickly and safely without jeopardizing compliance.

For executives, engineers, and procurement teams, the differences between the ASME U, S, and NBIC R stamps translate into real-world outcomes:

Choosing a contractor without the right stamps is essentially gambling with your plant’s compliance and your company’s reputation.

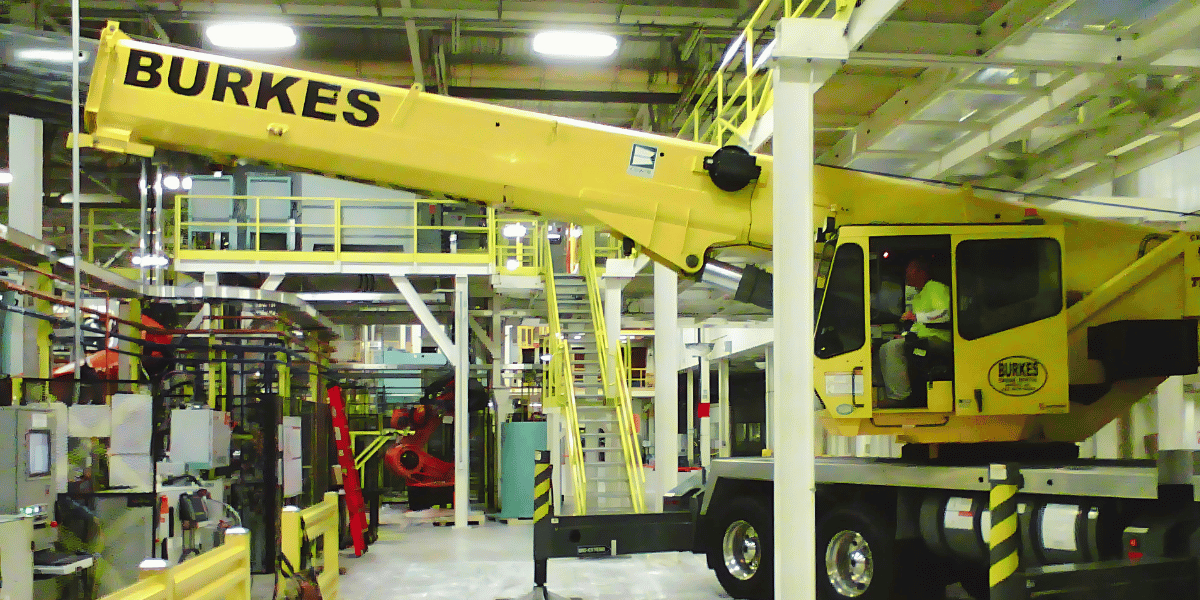

Burkes Mechanical is more than an industrial mechanical contractor in Alabama. We are a trusted partner for industries across the Southeast that need results they can rely on.

With an EMR of 0.41 and zero OSHA citations in the past three years, we do not just check boxes. We set the benchmark for safety and reliability across the Southeast.

The difference between the U, R, and S stamps comes down to scope:

For plant managers, project engineers, and procurement leaders, these stamps are not technical trivia. They are critical factors in compliance, safety, and operational success. Understanding the difference means you can hire the right contractor the first time, avoid inspection failures, and keep projects on schedule.

When your next project calls for ASME-certified fabrication or repairs, partner with a contractor who brings more than qualifications. Burkes Mechanical delivers stamped equipment, full-scope industrial services, and a proven safety record that protects your operation.

%20(1).png)

If you are responsible for pressure vessels in your plant, you have likely heard about ASME U and National Board R stamps. Both certifications are...

When it comes to industrial construction and maintenance, choosing between a national contractor and a trusted local partner can make or break a...

Modular construction reduces plant downtime by shifting the majority of fabrication and assembly offsite, allowing facilities to maintain operations...