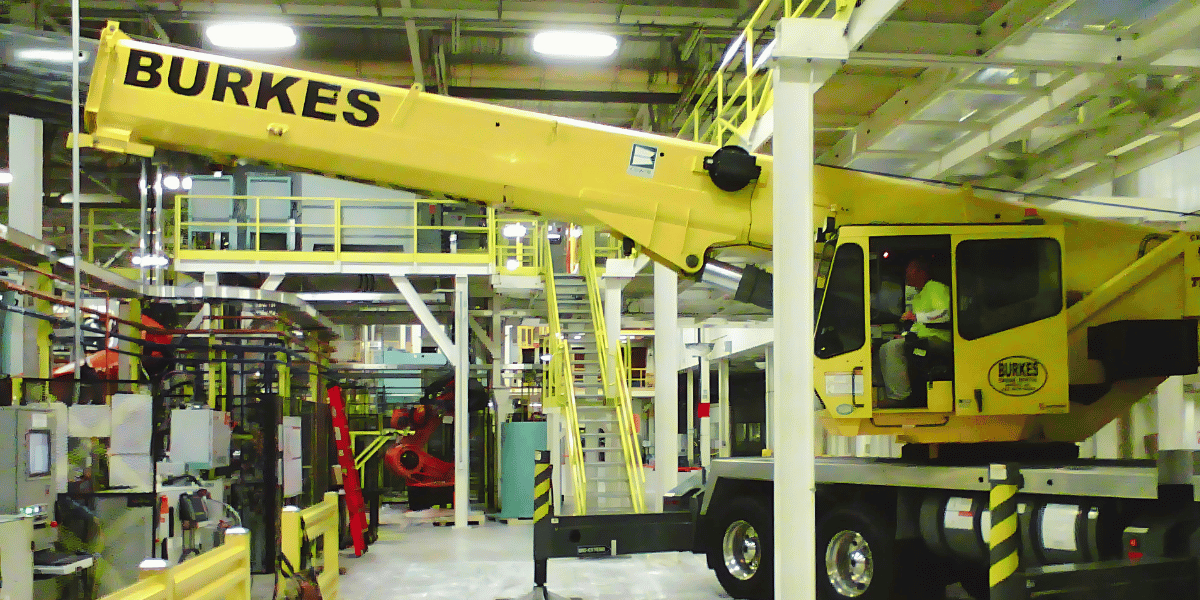

Burkes vs National Contractors: Why Local Knowledge and Fleet Matter

When it comes to industrial construction and maintenance, choosing between a national contractor and a trusted local partner can make or break a...

Table of Contents

Experience Modification Rate (EMR) matters to every client hiring a subcontractor because it directly reflects that company’s safety record, claim history, and the level of risk they bring to your jobsite and budget. In this blog post, we will break down what EMR is, how it affects insurance costs and project performance, which EMR benchmarks you should look for, and the specific questions you should ask every subcontractor about their EMR so you can make more confident, safer hiring decisions.

An EMR (experience modification rate) is a numerical factor used by insurance companies to calculate a subcontractor’s workers’ compensation premium. The number reflects past claim history, frequency of incidents, and expected future risk.

Many plant operators assume EMR is purely an insurance number—but it’s much more. It also functions as a proxy for safety performance and risk profile of a subcontractor. When you’re selecting a subcontractor for maintenance, turnaround or ongoing operations work, understanding their EMR helps you gauge their safety culture and the likelihood of incidents that could impact schedule, cost or compliance.

EMR is calculated using past payroll, classification rate (job category risk), actual losses (claims) and expected losses. Usually the calculation draws from the prior three years of claims data, excluding the most recent year. For example, frequent smaller claims often drive the EMR up more than one large claim.

The industry standard baseline is 1.0. A value below 1.0 indicates a subcontractor is safer than average; above 1.0 signals higher risk or poorer safety performance. Many owners now reject bids from subcontractors with EMRs above a certain threshold because it increases insurance cost and risk on the job. Burkes Mechanical maintains an EMR of 0.41, which reflects a significantly better-than-average safety record and a strong commitment to protecting people, schedules, and budgets.

EMR affects more than just insurance premiums—it influences your project’s risk, cost and timeline. A higher EMR means higher insurance premiums for the subcontractor, which often gets passed on to the owner or affects pricing competitiveness. From a plant manager’s perspective, hiring a subcontractor with a lower EMR means lower risk of safety incidents, less likelihood of lost time, regulatory scrutiny, or downtime that disrupts production.

Beyond cost and schedule, EMR reflects the subcontractor’s safety culture and operational rigor. A low EMR suggests the company has an effective safety program, controls in place, training, and leadership engagement. Conversely, a ballooning EMR could indicate systemic gaps in safety management, higher incident frequency, and therefore higher risk for your plant.

To properly vet subcontractors, plant managers should ask:

What is your current EMR?

Can you provide documentation of the EMR from the last 3 years?

What has your trend been: improving, stable or worsening?

What steps have you taken in your safety program to influence your EMR?

What is your plan if you exceed the project's insurance or risk thresholds?

When you engage a contractor with a strong EMR and safety program, you’re more likely to hit schedule milestones, avoid regrettable incidents, and maintain production integrity. Lower incident frequency means less downtime, fewer change orders and less insurance cost passed to your facility. It also helps your plant maintain good reputation and compliance profile.

In heavy-industrial sites where shutdown windows and risk tolerance are tight, subcontractor safety performance directly impacts your operations. A subcontractor’s safety record is one component—but aligning their safety systems with your plant’s standards elevates outcome. Consistent subcontractor performance with low EMR contributes to long-term partner reliability and cost control.

At Burkes Mechanical we integrate subcontractor EMR review into our pre-qualification and vendor management process. We don’t just ask for the number, we review the trend, their safety programs, their training, toolbox talks, incident investigation practices and leadership engagement.

Our process includes periodic audits of subcontractor performance, insurance verification, and aligning EMR metrics with our plant safety KPIs. We believe that by doing this up-front we reduce hidden project risk, maintain schedule integrity and deliver safer outcomes for our clients.

When it comes to industrial construction and maintenance, choosing between a national contractor and a trusted local partner can make or break a...

When you manage a plant or capital project, you live with the constant pressure of compliance, uptime, and safety. Boilers, tanks, and pressure...

%20(1).png)

If you are responsible for pressure vessels in your plant, you have likely heard about ASME U and National Board R stamps. Both certifications are...